NEWS

Jun 24, 2020

Nanotechnology-Enabled Welding and Manufacturing of High Performance Aluminum Alloys

High-performance nano-treated aluminum alloys made possible by MetaLi provide superior strength, weldability, processability, and corrosion resistance while maintaining light weight—further anchoring aluminum as an ideal material for the aerospace, automotive, and transportation industries.

Read more with the below source:

Mar 15, 2020

Metal’s new age

A breakthrough in metallurgy has vast implications for manufacturing lightweight products. Some things just seem out of the realm of possibilities, like the four minute mile, putting a man on the moon or air travel – and then it happens. That’s the case with the technology behind MetaLi, a company founded in 2016 and devoted to designing and manufacturing a new generation of super metals using nanotechnology, or as the company’s founder, Xiaochun Li, calls the process, “nanotech metallurgy.”

Read more with the below source:

Jan 18, 2020

Nanotechnology Meets Metal Fabrication

Li has researched nano-infused particles in various areas of manufacturing. But at this writing, his company is tackling challenges in aluminum fabrication. Specifically, it offers aluminum powders (2000, 6000, and 7000 series) for metal additive manufacturing; nano-treated high-strength aluminum alloys, including barstock, tube, and sheet; and, especially, nanoparticle-infused aluminum wires and rods for welding and additive manufacturing to weld the unweldable or print the unprintable.

Li is certainly aware of the broader implications of nanoparticle-infused metal. Smart use of nanotechnology might one day make metal become the best of all worlds: strong, formable, and weldable, all thanks to nano-sized peacemakers maintaining metallurgical calm and order.

Read more with the below source:

Dec 23, 2019

MetaLi’s Nanotechnology Enabled Welding of AA7075 is Featured in AWS Digest Readers’ Picks for 2019

The year saw some exciting research breakthroughs in this area, including a nanotechnology application for welding AA7075. (“Nanotech innovation could make previously unweldable alloys weldable,” April 24)

Read more with the below source:

Jan 9, 2020

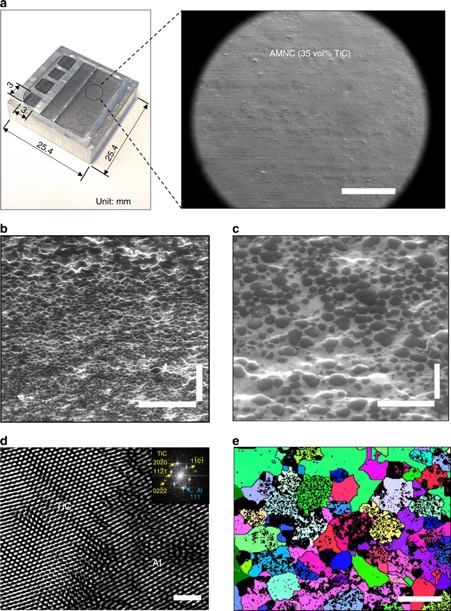

How Can Titanium Carbide Infusion Improve Welding Within Aluminum?

The new technique is just a simple twist, but it could allow widespread use of this high-strength aluminum alloy in mass-produced products like cars or bicycles, where parts are often assembled. Companies could use the same processes and equipment they already have to incorporate this super-strong aluminum alloy into their manufacturing processes, and their products could be lighter and more energy-efficient, while still retaining their strength

Read more with the below source:

Dec 11, 2019

FABTECH 2019 – Nano Technology for the Welding of Previously Unweldable High Strength Aluminum Alloys

During FABTECH, Light Metal Age spoke with Prof. Xiaochun Li, founder of MetaLi, about the company’s groundbreaking aluminum welding wire, which utilizes nano technology to enable the welding of previously unweldable high strength 7000 and 2000 aluminum alloys.

Read more with the below source:

Nov 11, 2019

FABTECH and metal fabrication’s future

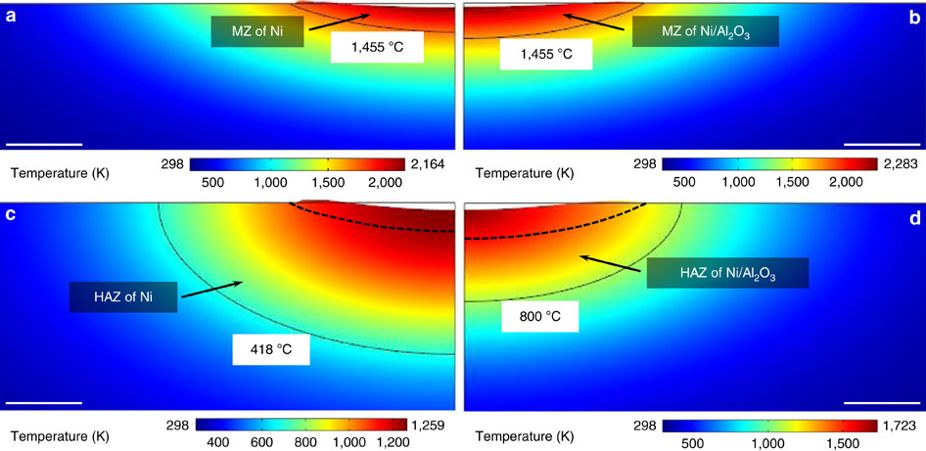

The technology, according to the company, effectively makes the unweldable weldable, with nanoparticles dispersed in such a way as to prevent postweld cracking. The technology is also being used in “super powders” for 3-D printing, but the theory behind the technology has grand implications.

Read more with the below source:

Sep 11, 2019

Aluminum with dispersed nanoparticles by laser additive manufacturing

The laser printed nanocomposite delivers a yield strength of up to 1000 MPa, plasticity over 10%, and Young’s modulus of approximately 200 GPa, offering one of the highest specific Young’s modulus and specific yield strengths among structural metals, as well as an improved specific strength and thermal stability up to 400 °C compared to other aluminum-based materials.

Read more with the below source:

Aug 26, 2019

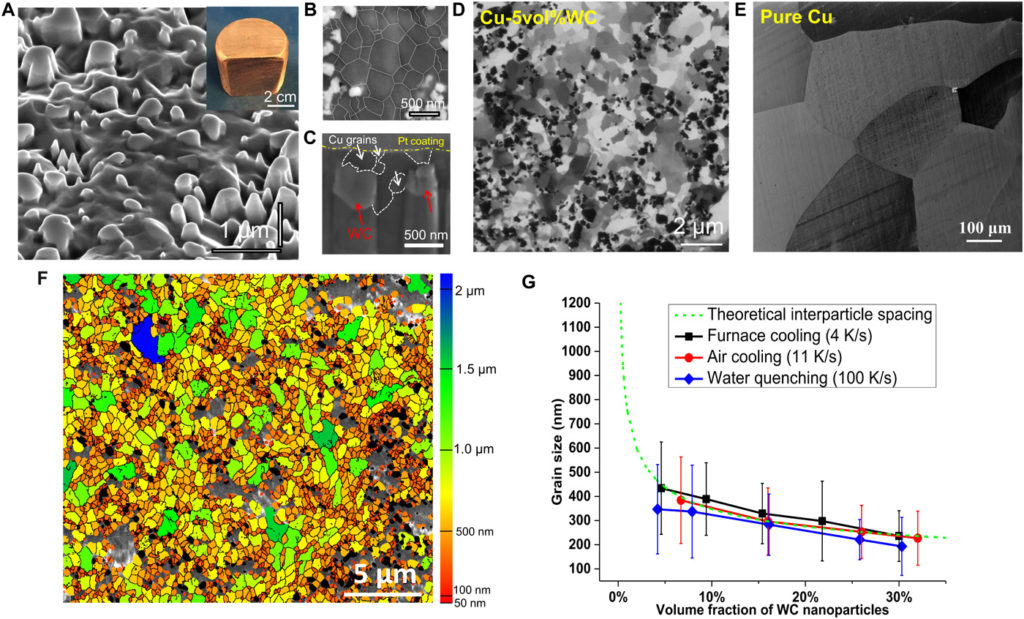

Breaking an ancient ceiling in metallurgy

Casting super strong metals with grain sizes down to nanometers during slow cooling. The study was published in Science Advances.

Read more with the below sources:

April 24, 2019

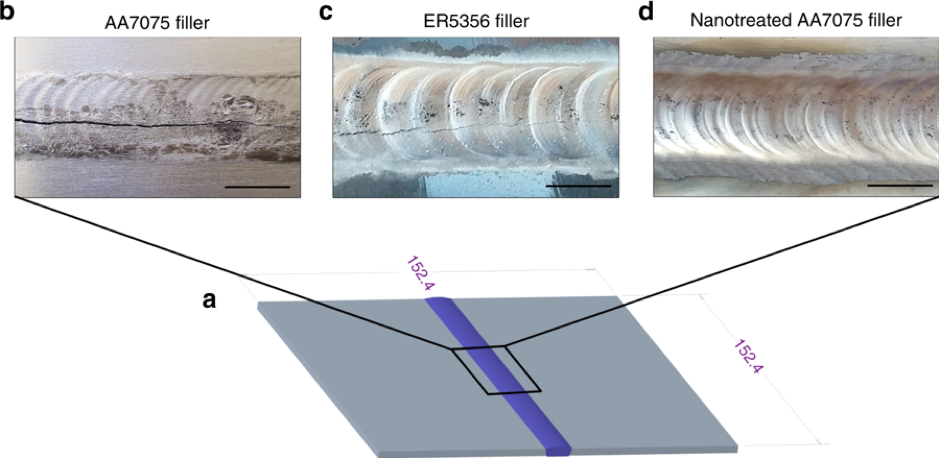

Nanotech innovation could make previously unweldable alloys weldable

AA7075 has an excellent strength-to-weight ratio, but the alloy has long been considered unweldable due to its susceptibility to hot tearing. When used in the aerospace industry, AA7075 is typically joined using rivets or bolts, and more recently friction stir welding (FSW) has successfully welded the alloy. However, due to FSW’s difficulty with complicated welds and difficult-to-access spaces, arc welding is highly desirable for joining AA7075.

Read more with the below source:

February 24, 2019

The New Metal Threatening Carbon Fiber Bike Frames | The GCN Tech Show Ep. 60

In this week’s show Jon and James take a look at the new aluminium alloy which can now be welded into bike frames, and could threaten the production of carbon fiber bicycles. And it’s got them thinking, what materials would you like to see bikes made from?

YOUTUBE LINK

January 24, 2019

Nanotechnology enables engineers to weld previously un-weldable aluminum alloy

Read more with the below sources:

January 18, 2017

Nanoparticles improve melting and solidification for manufacturing processes

Read more with the below sources:

Nov 10, 2016

Xiaochun Li : Smart Manufacturing at UCLA is a hub of a $140 million national effort

The institute will be headquartered in downtown Los Angeles in partnership with the city, led by the Smart Manufacturing Leadership Coalition and supported by UCLA’s leadership. It will include a national network of five regional manufacturing centers funded by $70 million from the U.S. Department of Energy and more than $70 million in matching funds from many of the institute partners.

READ MORE