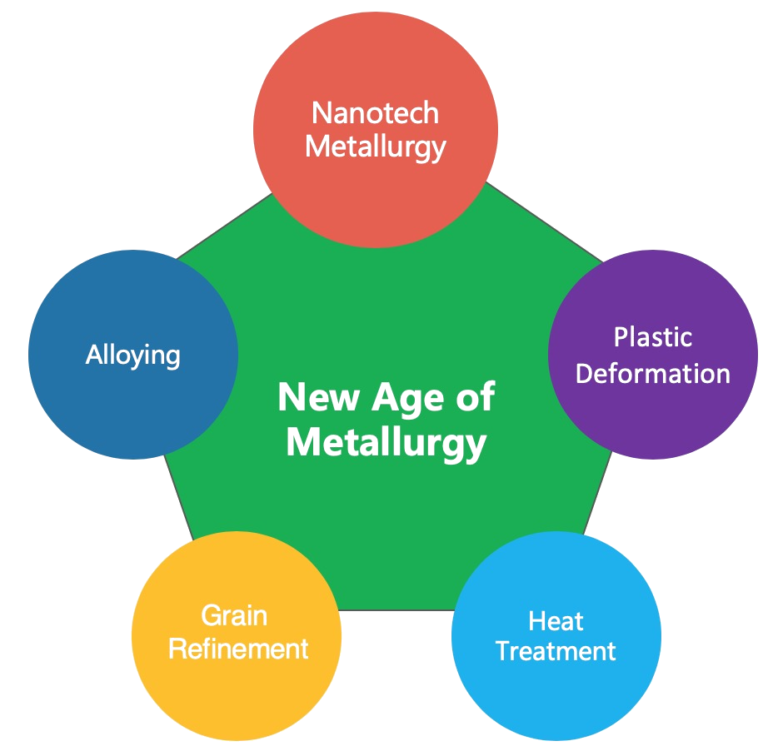

TECHNOLOGY

Nanotech Metallurgy

- High performance metals and alloys offer tremendous potential to improve energy efficiency and system performance for numerous applications. However, conventional metallurgical methods have reached certain limits.

- Nanotech Metallurgy is emerging to break traditional barriers and to revolutionize the metals processing and manufacturing technologies. Nanotech Metallurgy is an emerging interdisciplinary domain of materials science and engineering (especially metallurgy), manufacturing, and nanoscience and engineering that studies how nanophases (both ex situ and in situ) can be engineered and applied to significantly improve the processing/manufacturing, micro/nano-structures, and physical/chemical/mechanical behaviors of metals and alloys.

- Nanotech Metallurgy is creating a new and exciting processing/manufacturing space while pushing the performance envelope of metals to meet energy and sustainability challenges in human society.

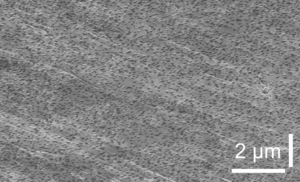

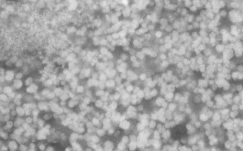

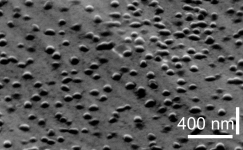

Thermally-Activated Dispersion and Stabilization of Nanoparticles in Metals

MetaLi solved the challenging issue of nanoparticle clustering in metals and achieved uniform nanoparticle dispersion in various metals and alloys, for example:

Emerging Nanotech Metallurgy In Industry

Emerging Nanotech Metallurgy has become a revolutionary metallurgical platform in the new century. Such a platform connects with existing industrial processes and large-scale manufacturing, promoting the widespread use of nanotech-enhanced super metals and leading a new metals revolution in the 21st century.

In-situ/ex-situ Nanoparticle Production

Nanoparticle Dispersion in Molten Metals

Solidification Processing of Super Metals

Thermomechanical Processing